How to connect operations to customer experience

Here’s How to Connect Operations to the Customer Experience

By 2017, field service became a competitive differentiator in industries like construction, telecom, and both medical and scientific devices. In fact, an average of 25% of these companies’ overall revenue now comes from service, according to a recent report from Worldwide Business Research. Fittingly, the role of the service technician has evolved to become one not only of technical skill but also of customer service, and even sales.

But in this role, no amount of training in sales, soft skills, or even interactive, on-site technologies alone gives them the oomph they need to get a leg up over the competition in 2017. Instead, as competition tightens, service organizations are looking internally to optimize back-end systems and processes to improve all lines of business. This includes interactions and long-term relationships with customers.

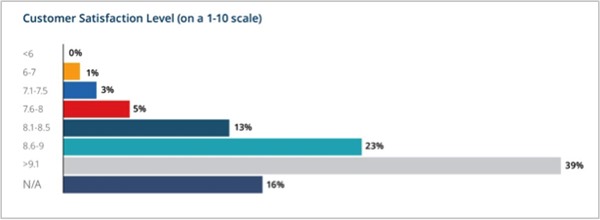

Qualifying and quantifying the customer experience—including customer satisfaction, loyalty, and customer lifetime value—is a deciding factor of field service performance, so much so that a rating scale—the Net Promoter Score (NPS)—was created to factor in the customer experience alongside traditional metrics. And while 62% of field services companies report an 8.6 rating or higher on a 10-point customer satisfaction scale, the NPS numbers are not so forgiving. Some companies don’t use the NPS system at all.

Companies that utilize field services need a new means for improving those NPS numbers. And as the majority of companies continue to look at technician training and connected technologies as the solution, industry leaders are taking the next big step—improving operations and the supply chain to enhance the customer experience.

Step 1 | Replace legacy systems.

One of the greatest inhibitors to technological progress in field services is legacy systems. While supply chain and fulfillment technologies continue to evolve, integrating them is made tedious or even impossible by incompatibility. But transitioning to emerging back-end technologies, which are now differentiators in terms of improving the customer experience, is no small feat.

For customers, timeliness and agile use of customer data are paramount. Today, sophisticated supply chain technologies can deliver the trustworthiness and dependability they demand, but the majority of field service companies (62%) struggle to do so because of legacy, complex, and CAPEX systems. This presents problems as organizations attempt to learn more about their customers, scale to accommodate additional customer data, and utilize that data to drive customer loyalty and revenue. With outdated systems, even sharing customer data between business units is difficult.

Field service companies can overcome these challenges by adopting new systems that support today’s proactive technologies, which allow organizations to monitor equipment remotely and automate processes associated with providing better services and creating a better environment for customers. Field service and operational stakeholders must take the first step in identifying a strategic path forward that will meet their objectives. They may also decide to bring in a third-party integration partner to help replace a legacy system with a cost-effective, scalable solution. But no matter the approach, they will require executive ‘buy in’ to move forward, which we will discuss in further detail.

Step 2 | Implement cutting-edge supply chain solutions.

In 2017, organizations that can identify the relationship between the supply chain and customer satisfaction have the competitive advantage. With this awareness, they can pinpoint correlations and improve the ways in which technicians deliver customer experiences.

Consider this—some organizations have no more than a few hundred technicians in the field. They rely on only a handful of skilled employees to keep their service business running. But a smaller customer base means more specific customer needs that those organizations must meet to differentiate themselves from larger competitors. Sophisticated supply chain solutions can be the contributing factor to their success.

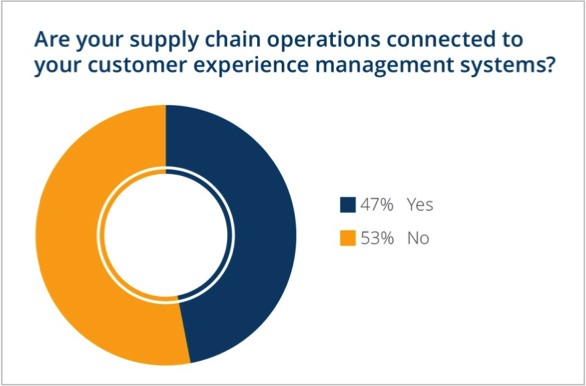

Supply chain technologies enable timeliness and agile use of customer data to proactively meet the changing requirement of customers. But right now, more than half of organizations (53%) claim their supply chains and customer experiences are not even connected. As customer-facing service methods and technologies begin to equalize across the industry, this is becoming a real problem.

For example, customer service centers have evolved to become an integral part of the supply chain in terms of customer service, where customers not only retrieve information in a traditional way but require guidance and assistance over the entire course of their repair issues. As a result, those representatives must be equipped with integrated technologies that provide the tools they need to help customers, and a unified view of all customer data so that they can pinpoint issues and develop solutions in real time.

Step 3 | Integrate supply chain functions and proactive, customer-facing technologies.

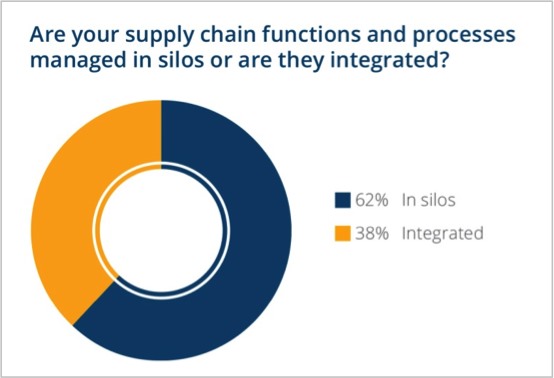

The right integrated technologies help organizations gain more visibility into their operations and perform more effectively. But most field service companies (62%) claim their supply chain functions and processes are managed in silos. That poses a problem, because service organizations that fail to centralize both operations and customer data cannot effectively connect the supply chain to the customer experience.

Most companies don’t realize that improving operations should begin with looking at what are the requirements for exceptional customer service. Then companies can develop a strategy to streamline their operational structure to meet those needs. Succeeding in this will invariably require an integrated supply chain that seamlessly connects with the customer-facing technologies that deliver on those service requirements. This empowers your teams to provide customers with what they want, when they want it.

Your team uses mobile technologies to provide product, service, and customer information, fleet monitoring equipment to track teams, and project management solutions to determine both repair times and progress, among other solutions. Integrating them with the back end will become a critical part of your business and your operations.

Step 4 | Centralize data for a 360˚ view of customers and business units.

Effectively processing customer data enables service organizations to predict how many technicians they require for specific jobs, what kind of expertise is required, and of course, everything they need to know about the customer. But while centralizing data for a complete view of customer behavior is becoming a standard best practice in other industries, the vast majority of field service companies do not have a centralized customer view.

In fact, 92% claim they need to access multiple views to see customer data, interactions, inventory, logistics, and analytics across business functions, geographies, and products. Consequently, they are unable to identify key opportunities to improve processes and the customer experience.

Knowledge management and CRM technologies can unify information from front-end and back-end systems to provide an exceptional window into your data. This in turn can be utilized by any number of teams, be they in operations, in customer service roles, or out in the field. Unifying customer data across the business in this way increases your teams’ opportunities for delivering an exceptional customer experience—no matter who is interacting with a customer at any given time, and at any stage of the service cycle. Needless to say, joining the remaining 8% of companies who do have access to these multiple views will give any field service company an advantage over the vast majority of competitors.

Step 5 | Utilize both internal and back-end systems to improve the customer experience.

In 2016, companies focused on developing customer-facing technologies like remote diagnostics, technician connectivity, mobility, and even Internet of Things (IoT). Now, the differentiating trend is aligning sophisticated, integrated back-end systems with lines of business, and considering how those systems also drive exceptional customer experiences.

Field service companies are divided in terms of whether or not their supply chain operations are connected to their customer experience management systems. Only 47% of companies claim they are connected, while the rest claim they are not. This is a prevailing problem for field service companies in terms of differentiating themselves from their competitors.

But companies with stakeholders who have developed a clear path forward, and who have factored in the customer experience in identifying how they will adopt and integrate new technologies, will quickly align operations with the customer experience and edge out their less fortunate competitors. More importantly, they will provide a streamlined experience for customers that will limit internal complications and establish a precedent for their customers moving forward.

Press Ahead!

There is one more essential factor in successfully connecting operations to the customer experience, and that’s leadership. To establish that strategic path, executives must both understand and ‘buy in’ to the new ideas and technologies that will help deliver a higher level of service performance. But first, both supply chain and field service stakeholders must look at the operational structure of an organization and develop a strategy to streamline the service process. Only then can executives engage with management, employees, and third-party vendors to share that vision and lift that company to a higher level of service quality.

Make the connection! Discover how leading field service companies achieve customer satisfaction, loyalty, and exceptional performance with supply chain technologies.